The string action is adjusted perfectly with the help of the truss rod, saddle and bridge inlay and the frets are still buzzing?

A common phenomenon is a tiny hump at the neck-body transition. This is due to the fact that in the course of time all the woods have settled a little, only where the base of the neck is glued to the block inside the guitar, the material could not shrink as much as on the rest of the guitar, thus the fingerboard was slightly raised. Most of the time it rattles from about the 7th fret, in extreme cases the sound dies off completely at 12th/13th fret.

All you can do now is remove the frets, plane the fingerboard back into the correct alignment, i.e. remove all unevenness, and re-fret the guitar. Here you can see how it's done.

Over the entire fingerboard down to the point of being pressed down, the strings clank, the G string in particular.

The strings have been removed.

Disassembled machine heads

Removal of the frets

Bare fingerboard

Leveling. First of all, the bumps are levelled off. You can clearly see that there was a hump

Then the entire fingerboard is smoothed with the sanding block into the correct alignment. The block is coated with rough sandpaper on the side facing the fingerboard.

The depth of the slots is measured with a metal tape measure.

... and reworked

Special saw for fingerboards with binding.

Fret wire is cut to size

The new frets in the right order

The tang for the slot is removed at the edge

Frets ready for mounting

Inserting the frets with the wooden hammer

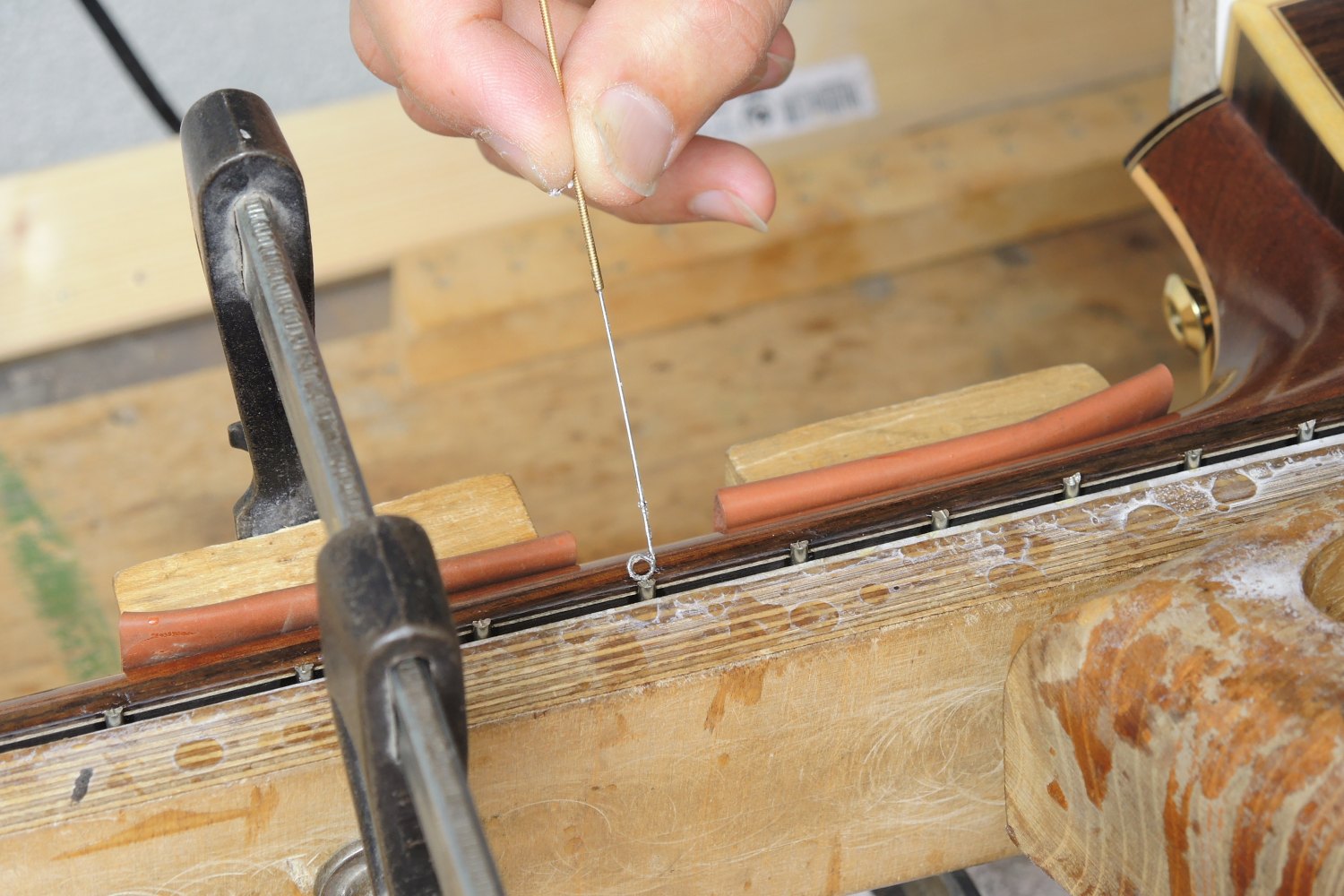

Superglue is used to fix the protruding ends of the frets to the binding.

The frets are filed level with the fingerboard.

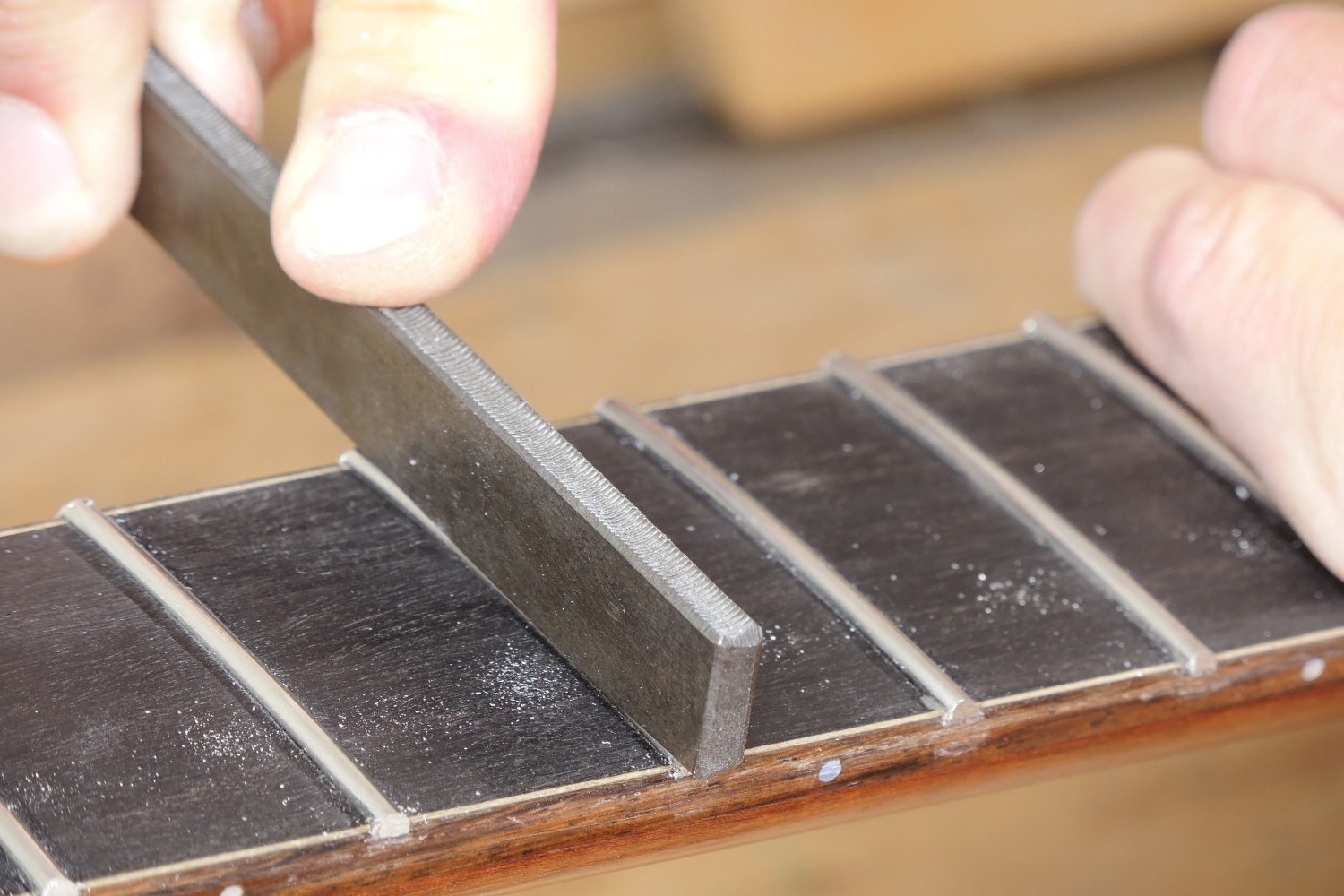

The frets are dressed with a block file (aligned to a uniform height).

Profile file with gouge

The small area on the frets created during dressing is re-profiled to re-create an exactly defined point of support.

The lateral burr created by flush filing is removed.

The finished fingerboard

… and the newly strung guitar.